Injection Molding Maintenance Certification Package

Injection Molding Maintenance Certification Package

The courses included in this package cover many important topics, including: injection molding safety, maintenance, robotics, drying, machinery, materials, purging, robotics, parameters, and hydraulics.

This package is great for all maintenance personnel, such as maintenance technicians, maintenance managers, as well as process techs — preparing them for the Injection Molding Maintenance Certification Exam, which is included in the package.

List Price: $2,861.00

Our Price: $1,297.00

You save $1,564.00!

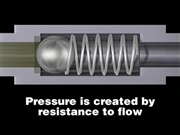

Injection Molding Hydraulics

Injection Molding Hydraulics

These courses demonstrate the importance of hydraulics and the required proper maintenance of hydraulic components. Machine operators will learn ways to reduce wear on hydraulic components and become familiar with hydraulic print reading and theory.

Injection Mold Maintenance

Injection Mold Maintenance

Proper mold maintenance is covered in detail and stresses important safety considerations for mold handling; before, during, and after a production run. Participants will learn techniques for

extending tool life and increasing its productivity.

Injection Molding Machine Maintenance

Injection Molding Machine Maintenance

This course will show users the proper approach to machine, fluid, platen, screw and barrel maintenance. Participants are also shown newer technologies; such as laser leveling, ultrasonic tie bar stretch measuring, and portable machine process monitors.

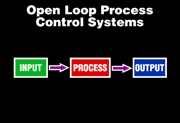

Understanding Process Control Systems

Understanding Process Control Systems

Molders will be able to make more educated choices relating to

closed loop process control systems after taking this online course. How process control reduces variation is also covered.

The 5S System SkillSet™ Series

The 5S System SkillSet™ Series

The 5S System is a critical component of Lean Manufacturing used by successful manufacturing facilities worldwide. It consists of 5 simple and concise steps – Sorting, Straightening, Sweeping, Standardizing, and Sustaining – that can help your facility reduce clutter and waste and, ultimately, increase efficiency and productivity.

Injection Mold Maintenance (Español)

Injection Mold Maintenance (Español)

Muchos moldeadores de inyección no prestan suficiente atención al mantenimiento del molde, lo que genera pérdidas de tiempo y dinero. Este programa brinda permite que el participante comprenda como realizar un correcto mantenimiento del molde.

The 5S System SkillSet™ Series (Español)

The 5S System SkillSet™ Series (Español)

5S es un componente crítico de Lean Manufacturing. El sistema 5S es utilizado por plantas de fabricación exitosas en todo el mundo. Consta de cinco pasos sencillos y concisos (clasificar, ordenar, limpiar, estandarizar y sostener) que pueden ayudar a sus instalaciones a reducir el desorden y el desperdicio y, en última instancia, aumentar la eficiencia y la productividad.