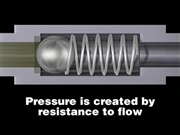

Injection Molding Hydraulics

Injection Molding Hydraulics

These courses demonstrate the importance of hydraulics and the required proper maintenance of hydraulic components. Machine operators will learn ways to reduce wear on hydraulic components and become familiar with hydraulic print reading and theory.

Injection Mold Maintenance

Injection Mold Maintenance

Proper mold maintenance is covered in detail and stresses important safety considerations for mold handling; before, during, and after a production run. Participants will learn techniques for

extending tool life and increasing its productivity.

Injection Molding Machine Maintenance

Injection Molding Machine Maintenance

This course will show users the proper approach to machine, fluid, platen, screw and barrel maintenance. Participants are also shown newer technologies; such as laser leveling, ultrasonic tie bar stretch measuring, and portable machine process monitors.

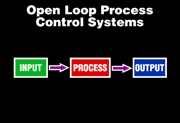

Understanding Process Control Systems

Understanding Process Control Systems

Molders will be able to make more educated choices relating to

closed loop process control systems after taking this online course. How process control reduces variation is also covered.

Injection Mold Maintenance (Español)

Injection Mold Maintenance (Español)

Muchos moldeadores de inyección no prestan suficiente atención al mantenimiento del molde, lo que genera pérdidas de tiempo y dinero. Este programa brinda permite que el participante comprenda como realizar un correcto mantenimiento del molde.

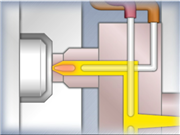

Tooling Basics: Common Mold Types

Tooling Basics: Common Mold Types

This course explains the three basic mold designs and their construction. Each design’s common uses, advantages and disadvantages are discussed. Various hot runner systems and configurations are covered.