Understanding Plastics Materials

Understanding Plastics Materials

This course will benefit any personnel that's involved with material handling and describes the effects that moisture can have on molded part properties during processing. Polymer classification and what occurs during processing for each type is also explained.

Material Drying Technology for Scientific Molders

Material Drying Technology for Scientific Molders

Material handlers need to know how different types of polymers are best dried and prepared for reliable processing. These courses show participants how proper plastics material handling and drying is critical to produce a consistent product.

Single Screw Extrusion Series

Single Screw Extrusion Series

Designed to benefit anyone working in a single-screw extrusion production environment, these programs use animation and actual production footage to demonstrate complex concepts. Important safety precautions are stressed throughout these training programs.

Twin Screw Extrusion Series

Twin Screw Extrusion Series

Designed to benefit anyone working in a twin-screw extrusion production environment, these programs use animation and actual production footage to demonstrate complex concepts. Important safety precautions are stressed throughout these training programs.

Math for Extruders

Math for Extruders

This two-part online training program was created for all personnel within the extrusion industry who would like to fine-tune or expand their math skills. The wide range of topics covered apply directly to the everyday operations that take place at any extrusion facility.

The 5S System SkillSet™ Series

The 5S System SkillSet™ Series

The 5S System is a critical component of Lean Manufacturing used by successful manufacturing facilities worldwide. It consists of 5 simple and concise steps – Sorting, Straightening, Sweeping, Standardizing, and Sustaining – that can help your facility reduce clutter and waste and, ultimately, increase efficiency and productivity.

Certification Exam for Single Screw Extrusion Professionals

Certification Exam for Single Screw Extrusion Professionals

Routsis Training’s globally recognized Professional Certification demonstrates a broad-spectrum understanding of the extrusion industry.

In order to attain certification, candidates must have a working knowledge of extrusion safety, machinery, processing, materials, and quality — and demonstrate a solid understanding of current industry best practices. This edition of the certification exam focuses on Single Screw Extrusion. We also offer a Twin Screw Extrusion version.

Certification Exam for Twin Screw Extrusion Professionals

Certification Exam for Twin Screw Extrusion Professionals

Routsis Training’s globally recognized Professional Certification demonstrates a broad-spectrum understanding of the extrusion industry.

In order to attain certification, candidates must have a working knowledge of extrusion safety, machinery, processing, materials, and quality — and demonstrate a solid understanding of current industry best practices. This edition of the certification exam focuses on Twin Screw Extrusion. We also offer a Single Screw Extrusion version.

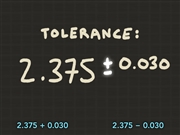

Certification Exam for Single Screw Extrusion Quality

Certification Exam for Single Screw Extrusion Quality

The ultimate goal of any extrusion operation is to deliver high-quality plastic parts to your customers. In order to pass this exam, candidates must demonstrate a working knowledge of extrusion quality — including safety concerns, the extrusion process, plastics materials, mathematics, print reading, and the use of measuring tools for part inspection. This exam is specifically geared toward single screw extrusion processes.

Certification Exam for Twin Screw Extrusion Quality

Certification Exam for Twin Screw Extrusion Quality

The ultimate goal of any extrusion operation is to deliver high-quality plastic parts to your customers. In order to pass this exam, candidates must demonstrate a working knowledge of extrusion quality — including safety concerns, the extrusion process, plastics materials, mathematics, print reading, and the use of measuring tools for part inspection. This exam is specifically geared toward twin screw extrusion processes.

The 5S System SkillSet™ Series (Español)

The 5S System SkillSet™ Series (Español)

5S es un componente crítico de Lean Manufacturing. El sistema 5S es utilizado por plantas de fabricación exitosas en todo el mundo. Consta de cinco pasos sencillos y concisos (clasificar, ordenar, limpiar, estandarizar y sostener) que pueden ayudar a sus instalaciones a reducir el desorden y el desperdicio y, en última instancia, aumentar la eficiencia y la productividad.

Introduction to Plastic Materials

Introduction to Plastic Materials

This program explains how and why plastics are different and cites several different types of polymers and processing considerations.

Introduction to Troubleshooting

Introduction to Troubleshooting

This training program provides participants with a better understanding of the different options and capabilities associated with automation.

Barrel Purging for Extruders

Barrel Purging for Extruders

The 3 courses in this series introduce participants to a scientific approach to barrel purging, covering various purging techniques and procedures. Participants also learn about the 4 phases of barrel purging. Purging compounds commonly used in the industry are also discussed — including the advantages/disadvantages of each type.