An Introduction to Injection Molding

An Introduction to Injection Molding

The primary focus of this training program is to introduce newcomers to the plastics industry and the day-to-day operations of a typical injection molding facility.

Injection Molding Basics

Injection Molding Basics

Our Basics series covers the three major aspects of injection molding; the injection molding machine, the molding process, and the injection mold. Important safety precautions are stressed throughout these training programs.

Understanding Plastics Materials

Understanding Plastics Materials

This course will benefit any personnel that's involved with material handling and describes the effects that moisture can have on molded part properties during processing. Polymer classification and what occurs during processing for each type is also explained.

Establishing a Scientific Injection Molding Process

Establishing a Scientific Injection Molding Process

The course teaches how to establish and maintain a scientific processing that properly decouples 1st stage fill from 2nd stage pack, which leads to improved process efficiency and much higher repeatability.

Process Documentation for Scientific Molders

Process Documentation for Scientific Molders

Proper documentation and the procedures associated with documenting a scientific molding process are critical for creating and maintaining a robust scientific injection molding process. This course also teaches the differences between machine-dependent and machine-independent process parameters and how they are obtained.

Processing Parameters for Scientific Molders

Processing Parameters for Scientific Molders

This 3-part training program explains how processing parameters are involved with a scientific injection molding process and will benefit die setters, process technicians, maintenance personnel, engineers, and anyone else that interacts with the control panel.

Injection Mold Setup for Scientific Molders

Injection Mold Setup for Scientific Molders

This comprehensive 2-part program is essential for anyone involved with die setting, including process technicians and supervisors. Topics covered: safety, preparation, documentation, mold removal, mold installation, and process startup.

Automation & Robotics for Scientific Molders

Automation & Robotics for Scientific Molders

Learn the different options and capabilities associated with robotics and are used to streamline production within the injection molding industry. Guarding and safety considerations are also covered in detail.

Purging for Scientific Molders: Intermediate

Purging for Scientific Molders: Intermediate

Designed specifically for injection molders, Routsis Training’s intermediate-level purging courses introduce a scientific approach to material purging.

These courses discuss important purging concepts and detail common procedures for purging plastic material from the injection screw, barrel, and nozzle — and techniques for cleaning hot runner systems and gate drops.

Purging for Scientific Molders: Advanced

Purging for Scientific Molders: Advanced

Building on the concepts outlined in the intermediate purging courses, these advanced online lessons continue with a detailed discussion of common purging compounds — including resin-based, mechanical, and chemical compounds.

In the final course, users are shown how to effectively compare different purging procedures and compounds – and guided through completion of the Purging Analysis Worksheet, which is included with the online course.

Material Drying Technology for Scientific Molders

Material Drying Technology for Scientific Molders

Material handlers need to know how different types of polymers are best dried and prepared for reliable processing. These courses show participants how proper plastics material handling and drying is critical to produce a consistent product.

Electric Injection Molding for Scientific Molders

Electric Injection Molding for Scientific Molders

Participants will learn all of the benefits and capabilities of modern all-electric injection molding machines. Users will also be prepared to make more effective decisions for optimizing any process that’s running on an electric machine.

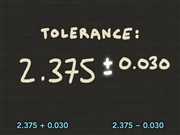

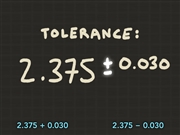

Math for Scientific Molders

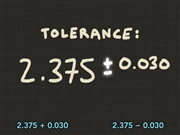

Math for Scientific Molders

Created for plastics industry personnel to fine-tune and expand their math skills, these courses cover a wide spectrum of math-related topics that are dealt with on a daily basis at any facility.

Scientific Troubleshooting for Injection Molders

Scientific Troubleshooting for Injection Molders

Participants are provided with the knowledge base required to identify and troubleshoot over twenty-five of the most common injection molded part defects. Users will also come away with a better understanding of how to best process, document and maintain a reliable scientific injection molding process.

Processing For Profit

Processing For Profit

Processors and technicians are presented with industry-proven procedures and techniques which can be used to easily improve the efficiency and profitability of any molding application.

Scientific Molding SkillSet™ Series

Scientific Molding SkillSet™ Series

The Scientific SkillSet™ Series is a unique learning experience that combines detailed, step-by-step online instruction with practical hands-on labs and worksheets. Each course/worksheet combinations focuses on developing processing-related skills that translate directly to troubleshooting, optimizing and documenting any injection molding process.

RJG's DECOUPLED MOLDING℠ Series

RJG's DECOUPLED MOLDING℠ Series

This four-part training program starts with the major components of the molding process, and progresses to systematic troubleshooting. Molders will learn how to optimize any injection molding process that uses Decoupled Molding℠.

Intelligent Molding Series

Intelligent Molding Series

Produced for technicians and process engineers, these courses teach how to evaluate the capability and repeatability of a given injection molding machine, injection mold, or injection molding process. These courses will greatly benefit any participant of the Master Molder℠ Certification Series – either as a primer or as follow-up training.

RJG’s eDart™ Overview

RJG’s eDart™ Overview

This course was created for production personnel that monitor and optimize injection molding processes equipped with RJG’s eDART™ process controllers. Participants will be better prepared to establish improved process stability and advanced machine and process analysis.

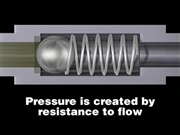

Injection Molding Hydraulics

Injection Molding Hydraulics

These courses demonstrate the importance of hydraulics and the required proper maintenance of hydraulic components. Machine operators will learn ways to reduce wear on hydraulic components and become familiar with hydraulic print reading and theory.

Injection Mold Maintenance

Injection Mold Maintenance

Proper mold maintenance is covered in detail and stresses important safety considerations for mold handling; before, during, and after a production run. Participants will learn techniques for

extending tool life and increasing its productivity.

Injection Molding Machine Maintenance

Injection Molding Machine Maintenance

This course will show users the proper approach to machine, fluid, platen, screw and barrel maintenance. Participants are also shown newer technologies; such as laser leveling, ultrasonic tie bar stretch measuring, and portable machine process monitors.

Understanding Process Control Systems

Understanding Process Control Systems

Molders will be able to make more educated choices relating to

closed loop process control systems after taking this online course. How process control reduces variation is also covered.

Blow Molding 101 Package

Blow Molding 101 Package

Blow Molding 101 provides employees with broad-based training on the extrusion blow molding; covering the machine, process, mold and math skills. Anyone working with production equipment or handling the material will greatly benefit from this package.

List Price: $744.00

Our Price: $447.00

You save $297.00!

Extrusion Blow Molding Series

Extrusion Blow Molding Series

Developed in collaboration with The Society of Plastics Engineers (SPE), these three courses will provide a thorough understanding of what’s involved in the Extrusion Blow Molding process.

Using standard industry terms and practices, with an emphasis on safety, these courses are essential for all personnel involved with Extrusion Blow Molding.

Math for Blow Molders

Math for Blow Molders

This two-part online program was created for all personnel within the blow molding industry who would like to expand or fine-tune their math skills.

Single Screw Extrusion Series

Single Screw Extrusion Series

Designed to benefit anyone working in a single-screw extrusion production environment, these programs use animation and actual production footage to demonstrate complex concepts. Important safety precautions are stressed throughout these training programs.

Twin Screw Extrusion Series

Twin Screw Extrusion Series

Designed to benefit anyone working in a twin-screw extrusion production environment, these programs use animation and actual production footage to demonstrate complex concepts. Important safety precautions are stressed throughout these training programs.

Math for Extruders

Math for Extruders

This two-part online training program was created for all personnel within the extrusion industry who would like to fine-tune or expand their math skills. The wide range of topics covered apply directly to the everyday operations that take place at any extrusion facility.

Mold Design & Mold Making Series

Mold Design & Mold Making Series

This comprehensive nine course series was created for tool designers, mold makers, engineers, part designers, and anyone involved in the tool procurement process. Participants will learn all of the different types of injection molds, contemporary machining methods, and many of the available mold components. A tool design methodology and a sample mold specification guide is also provided.